I am trying to fix the circuit board on my universal remote control. The solder that holds the Red Positive wire (+) and the Black Negative wire (-) constantly breaks. The part of the circuit board I am having trouble with is where the batteries go to give the remote power. I soldered the wires back to the battery + and – joints multiple times but it breaks after I insert the batteries. When I insert the batteries, this puts slight pressure on the battery compartment area and the wires break free from the solder. Can you tell me if there is a more reliable or permanent way to solder wires so they don’t fall off or break if strain is applied?

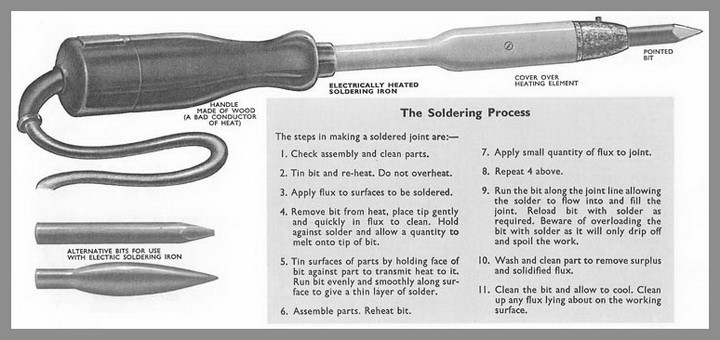

It sounds as if you may not be soldering properly or you may have bad solder wire. You can try using a high quality multicore solder wire to be sure. Make sure your solder gun is getting hot enough. Also be sure that you use a rosin paste flux to assist the solder to properly attach to the solder joints.

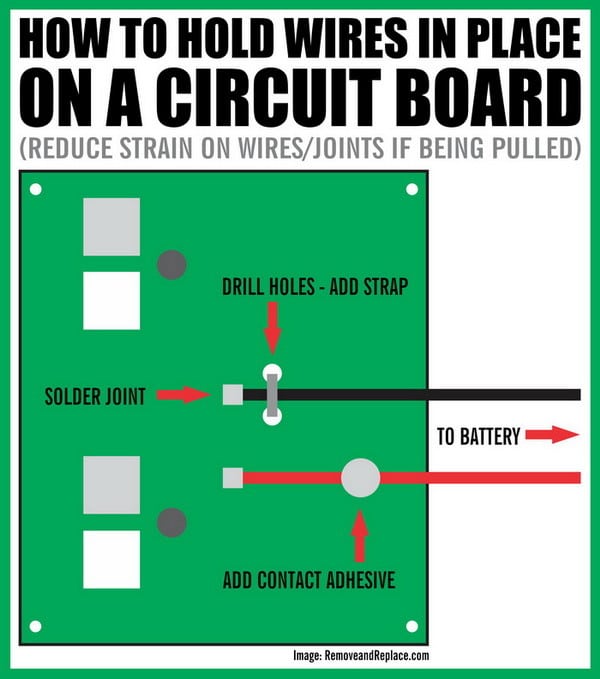

If the wires are being pulled on when you insert the batteries, you need to hold the wires down so they do not get pulled out. To prevent the wires from being pulled out again, drill 2 tiny holes on either side of each wire. Use tiny cable ties and slide it through the circuit board and wrap it around the wires to hold them in place. This will prevent the wires from being pulled out. If the wires are not long enough for this, see below for a few other techniques.

Methods to hold soldered wires in place to provide strain release is:

(Make sure the adhesive items below are clear of the soldered joints)

1. Use a drop of hot glue from a glue gun to hold the wires.

2. Try a drop of contact adhesive to hold wires in place.

3. Drill 2 holes for each wire and thread each wire through and then back before you solder.

4. Drill a hole on each side of the wire, add a small cable tie to secure.

5. You could desolder the old wires and solder on longer wires.

NOTE: This method of soldering can work well on e-cig vaporizer batteries, electronic circuit experiment boards, raspberry pi, TV remote controls, radio controlled planes, helicopters, drones, and quadcopters. Basically any type of electronic circuit board that may be banged or bounced around.

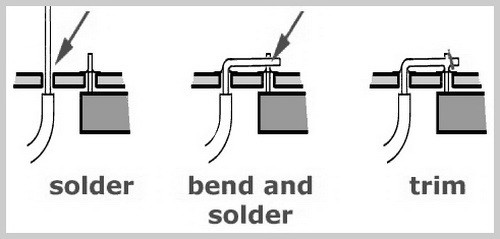

Soldering method for strain relief (when wire is pulled when component is used)

Soldering method for strain relief (when wire is pulled when component is used)

How To Solder A Circuit Board

How To Solder 2 Stranded Wires Together

How to Remove Solder

If a joint is soldered properly, it will be very difficult to pull it apart. Be sure to use a quality multicore solder and quality flux. Be sure the joint is super clean and has no grease or gunk on it before applying solder. Use high heat and a drop of solder on it to be permanent. You can also try a solder that has the flux built into it. The quality level of the solder wire you are using has a big affect on how strong the soldered joint will be. Use a high quality solder and a high quality soldering gun.

Do you know of other methods for soldering wires to joints on circuit boards? Please leave a comment below.

Leave a Reply